Are you looking for a versatile and powerful machine that can handle all your cutting and engraving needs? Look no further than the xTool P2, a CO2 laser cutter that’s perfect for both home use and small studios. With its exceptional compatibility with various materials, you can cut and engrave on both non-metal and metal surfaces, giving you optimal results.

The xTool P2 is packed with features such as dual-camera space positioning that boosts the precision of your projects. It comes equipped with two 16MP cameras that offer a real-time preview, reducing precision errors to just 0.3mm. Additionally, the panoramic camera generates a full-view image of the working area in just a few seconds, making your tasks more efficient.

Not only is the xTool P2 user-friendly, but it also ensures safe operation. The machine comes with a fully enclosed design, an emergency stop switch, and guides to maintain the machine’s optimal performance. Explore the world of laser cutting and engraving with the xTool P2, and elevate your creative projects with confidence and precision.

xTool p2 Main Features

The xTool P2 is a versatile CO2 laser cutter that offers you numerous features designed to make your projects easier, more efficient, and more precise.

One remarkable feature you’ll appreciate is the Roll Conveyor Feeder, which enables automatic passthrough for larger projects that require extra-large lengths of material. This unique feature helps speed up your workflow and reduces errors during the carving process.

Another important aspect of the xTool P2 is its dual-camera space positioning system consisting of a panoramic camera and a close-range camera. The panoramic camera generates a full view of the working area within just 3 seconds, while the close-range camera provides a real-time live preview for greater precision.

The xTool P2 laser cutter is equipped with an auto-focus feature that ensures optimal cutting power and precision. This feature, coupled with a 55W laser module, is ideal for cutting and engraving on a wide range of materials, including non-metals and metals. You’ll also find the xTool P2 laser cutter to be highly compatible with a range of available rotary attachments, making it even more versatile for your projects.

Wi-Fi connectivity makes it incredibly convenient for you to operate and manage the P2 laser cutter remotely, allowing you to focus on your projects without the hassle of wired connections. The xTool P2 is equipped with a spacious working area and is designed for easy use, ensuring that you can take full advantage of its features for various creative applications.

Lastly, xTool offers free shipping on the P2 laser cutter, making it an attractive investment for both hobbyists and professionals alike. With ease of use, exceptional material compatibility, and advanced technology, the xTool P2 laser cutter is an excellent choice for all your cutting and engraving needs.

Material Compatibility

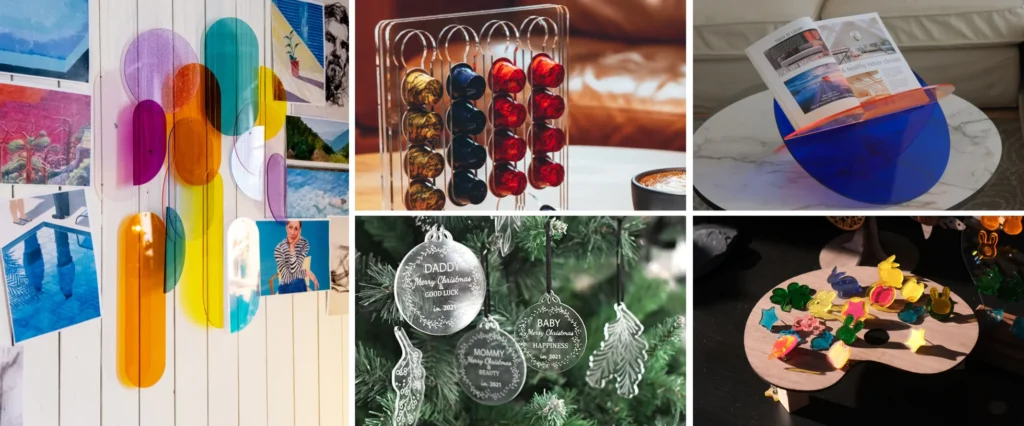

The xTool P2 CO2 laser cutter is a versatile machine, designed to cater to your cutting and engraving needs across a wide range of materials. Its extensive compatibility ensures that you can trust it to deliver exceptional results on both non-metal and metal materials.

When working with non-metals, you’ll find the xTool P2 perfect for cutting and engraving materials like wood, acrylic, leather, paper, and fabric. Its precision and efficiency will help you create intricate designs with ease, matching your artistic vision.

One standout feature of the xTool P2 is its ability to engrave on glass, making it ideal for creating personalized and decorative items. From wine glasses to mirrors, you can achieve stunning designs on glass surfaces, bringing your creative ideas to life. The CO2 laser technology used in the machine ensures high-quality engraving and smooth finishes on both flat and curved surfaces.

To extend its functionality and accommodate materials with different shapes, such as cylindrical and spherical objects, the xTool P2 can be equipped with a 4-in-1 rotary attachment. This attachment allows the machine to securely hold and rotate your workpiece so that you can engrave or cut intricate patterns seamlessly on round or cylindrical objects like bottles, jars, and mugs.

In summary, the xTool P2 CO2 laser cutter’s material compatibility, combined with its advanced functions, makes it a powerful and reliable machine for your cutting and engraving projects. With the xTool P2, you’ll have the confidence and precision needed to turn your creative imagination into reality.

Safe and Efficient Operation

When operating the xTool P2 safely and efficiently, first ensure that it is placed on a sturdy and level surface, preferably on a riser base. This helps maintain stability and allows for smooth navigation when using the device.

Before you start, inspect the processing area and ensure the air assist is properly functioning to keep the lens clean and maintain a high-quality cut. Air assist also helps to minimize burn marks on the material you are processing, and it improves overall cutting quality. It’s essential to familiarize yourself with the safety features and use them when needed to prevent accidents.

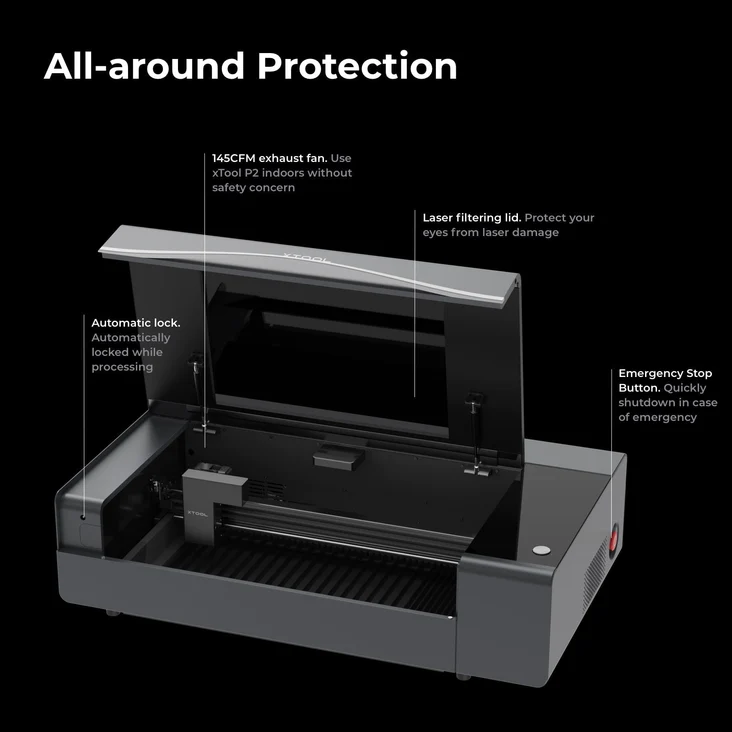

The xTool P2 is equipped with an emergency stop button which is an essential safety feature. In case of any emergencies, such as fires, or if you need to stop the machine immediately, press this button. The machine will stop working, allowing you to address any issues and avert potential hazards.

Fire safety should be a priority when operating the laser cutter. It’s crucial to never leave the machine unattended and have a fire extinguisher nearby. Be mindful of the materials you’re cutting or engraving, as some may be more flammable than others. Additionally, ensure proper ventilation is available to avoid smoke accumulation and fire hazards.

The xTool P2 has an emergency stop switch to keep you safe during the operation. Turn the switch to reset the machine when required. The device also has a Class I enclosure for safety, which means the entire laser system is enclosed to limit your exposure to the laser beam. It’s essential to always be cautious when working with Class IV lasers, which have higher rated power and potential risks.

Lastly, be mindful of the operating temperature when using the xTool P2. The device’s performance is optimal within specific temperature ranges, ensuring safe operation and avoiding any damage to materials or the machine itself. Make sure to regularly maintain the device to ensure its longevity and continuous safe operation.

Machine Specifications

The Xtool P2 comes with an impressive set of specifications that will satisfy your cutting and engraving needs. This 55W CO2 laser cutter provides optimal precision and efficiency when handling materials, including both metals and non-metals.

One of the key features of this machine is the ample bed size of 26 x 14 inches. This workstation comfortably accommodates a variety of materials and sizes, giving you more flexibility in your projects. The RA2 Pro software ensures compatibility with multiple file formats and offers an excellent user experience for designing and controlling the laser cutting process.

When it comes to speed, the Xtool P2 boasts an impressive engraving rate. Its automatic conveyor feeder and z-axis movement work together to guarantee smooth operation and accurate positioning. This minimizes errors and reduces the amount of time spent adjusting the machine.

The laser tube utilized in the P2 is designed for longevity, with a high-quality CO2 laser cutter ensuring a longer lifespan. This means you can enjoy the benefits of your investment for an extended period before considering a replacement. The laser spot of the P2 delivers precise cuts and engravings, while the maximum workpiece height ensures that you can work with a range of material thicknesses.

Your 3D models will come to life using the P2’s high image resolution and the ability to handle a large number of pixels. Connecting your device to the P2 is simple, thanks to the included USB cable and the user-friendly software interface.

Overall, the Xtool P2’s combination of software, bed size, engraving speed, positioning capabilities, and laser lifespan offers you a confident, knowledgeable, and user-friendly cutting and engraving experience.

Technical Precision & Focus

With the xTool P2’s smart dual-camera space positioning, you can confidently achieve high levels of precision in your projects. The two 16MP cameras offer a real-time preview and reduce the precision error to only 0.3mm. This level of vision precision ensures your designs are accurately transferred onto materials.

Your xTool P2 also provides a focus mode, allowing you to adjust the laser’s focal point for different material thicknesses. By doing so, you’re able to maintain exceptional engraving and cutting quality on various surfaces.

The cooling system is a vital part of the xTool P2, as it helps maintain a stable temperature during operation. The water-cooling system capacity, paired with an exhaust fan, efficiently dissipates heat to keep the machine functioning safely for an extended period.

Compatibility is essential, and the P2 has you covered. It supports various operating systems, including Windows, MacOS, and Linux, ensuring seamless integration into your existing workflow. The control software included with the machine simplifies the process of loading and managing your designs.

Lastly, the xTool P2 recognizes multiple supported file types, like SVG, DXF, BMP, and more. This versatility allows you to work with numerous design software suites and import your projects directly into the control software, making your laser cutting experience both effective and user-friendly.

Advanced Controls

With the xTool P2, you enjoy advanced control options that ensure precision and ease of use. The control system includes a state-of-the-art app, designed to make your experience with the laser cutter as seamless as possible. The app features an annular indicator for real-time monitoring of laser power and engraving speed, while the state display screen allows you to keep an eye on the progress of your projects through a clear, easy-to-understand progress bar.

The xTool P2 comes equipped with a water tank to maintain the ideal working temperature for the laser tube. It is essential to note that you need to add antifreeze to the water tank during colder periods. Antifreeze helps prevent any damage when the temperature falls below the freezing point. For optimal performance, it is recommended to use purified water in the water tank. The well-designed cooling system not only prolongs the life of the machine but also ensures consistent performance.

Another feature that sets the xTool P2 apart is its smoke exhaust pipe, which is built to protect your workspace from harmful fumes and keep it well-ventilated. This helps you maintain a clean environment for you and your projects.

By making use of the advanced controls available on the xTool P2, you can achieve impressive results on various materials and projects. Remember, staying up-to-date with your machine’s water tank and smoke exhaust maintenance is crucial in ensuring its longevity and optimal functioning.

Upgrade Possibilities

When it comes to upgrading your Xtool P2, there are several options available to enhance its performance and capabilities. One of these upgrades is the integration of a diode laser, which can greatly improve the cutting precision and speed of the machine. This type of laser is particularly useful for engraving on metal and other hard surfaces, offering a wider range of materials for your projects.

Another upgrade possibility for your Xtool P2 is the addition of smart cameras. These cameras can help optimize the calibration process and ensure proper material alignment before cutting, reducing the likelihood of errors during operation. This feature will enhance the overall efficiency and accuracy of your projects, making the most out of your machine.

If you’re working on larger projects that require longer pieces of material, you will benefit from the Xtool P2’s passthrough slot. This slot allows you to feed through extra-large lengths of material seamlessly, speeding up your workflow, and reducing potential errors during the carving process. This feature is unique to the Xtool P2 and is a significant advantage when tackling more extensive projects.

Finally, improving your Xtool P2’s capabilities further can be accomplished by replacing the standard rear cover with one that provides better ventilation and dust management. A well-ventilated machine ensures consistent performance and reduced wear and tear over time, extending the life of your machine and maintaining optimal cutting and engraving results.

By taking advantage of these upgrade possibilities, you’ll unlock the full potential of your Xtool P2, harnessing its power and versatility to achieve impressive results across a variety of applications.

Comparisons and Alternatives

When exploring alternatives to the xTool P2, one of the main competitors that you might come across is the Glowforge. Both machines are highly praised by small businesses and personal workshops, but there are some differences to consider when deciding which laser cutter suits your needs.

As you dive into the specifications, you’ll notice that the xTool P2 features a 55W CO2 laser cutter and a 26 x 14-inch bed size, making it one of the most powerful machines available. In comparison, the Glowforge Basic starts at a higher price of $3,995, but offers a live camera and can cut, engrave, and score on pieces up to 495 x 280mm. If you require a larger processing area, the xTool P2 seems to be a more fitting choice.

Water cooling is an essential part of any laser cutting machine’s operation, as it helps in preventing overheating and ensures consistent performance. Both the xTool P2 and Glowforge machines come with integrated water cooling systems, ensuring efficiency and longevity.

Calibration is a critical aspect of laser cutting accuracy, and both the xTool P2 and Glowforge machines offer user-friendly calibration features, ensuring precise and consistent results. However, some users have reported that the Glowforge may require more frequent recalibration, which could impact its ease of use and maintenance.

By keeping your priorities in mind, and considering factors such as price, processing area, water cooling, and calibration, you’ll be able to make a confident decision between the xTool P2 and its alternatives, like the Glowforge laser cutter.

XTOOL P2 Pricing

The xTool P2 CO2 Laser Cutter is available at different price points based on the configurations and accessories included.

On xTool’s US official website, the price for the xTool P2 Laser Cutter is listed at $4,599.00 with sometimes a special offer for a limited time. The package options available include the xTool P2 with the Automatic Conveyor Feeder and Riser Base, or with the RA2 Pro, Automatic Conveyor Feeder, and Riser Base, and there’s another option that includes the Smoke Purifier as well.

Ordering and Shipping

When you decide to purchase the xTool P2, you can place your order directly through their website. During the checkout process, you will have the opportunity to choose your desired configuration, such as the xTool P2+Automatic Conveyor Feeder (39″)+Riser Base. After selecting the appropriate options, you can proceed to confirm your total payment.

Make sure to take advantage of any available promotions and keep an eye out for potential discounts. By doing so, you can potentially save on your total payment. The website typically accepts various secure payment methods, so you can choose the one that suits you best.

Once your order is successfully placed, xTool will handle the shipping process. While waiting for your xTool P2 to arrive, consider downloading the guides and instructions to help you get ready to use your new laser cutter.

It’s essential to review the shipping policies and estimated delivery times to ensure you are aware of when to expect your xTool P2. Additionally, the website may offer customer support hotlines for both pre-sales and after-sales, which can assist you with any inquiries or concerns during business hours (Mon-Fri, 9:00-18:30 PDT).

In summary, the ordering and shipping process for the xTool P2 is user-friendly and efficient. By keeping track of your total payment and the available resources, you can ensure a smooth transition to using your new laser cutter. Good luck on your creative journey with the xTool P2!

Buy the xTool P2 in UK

You can access xtool P2 in the UK by visiting the brand’s official local store. The Shipping Policy ensures a smooth and efficient delivery experience for customers. xTool offer free shipping within the UK for orders over £99, with a reasonable £6.99 shipping fee for other orders. Delivery time typically takes 3-5 business days, while order processing may take up to 3 business days.

How to buy the xTool P2 in Germany and Austria?

If you live in Germany or Austria, xTool also has a local store. Customers in Germany and Austria can take advantage of xTool shipping services. Depending on the order size, DHL is the designated shipping provider for delivery. Here are the shipping costs :

Orders below €99 : Shipping cost of €6.99 / Orders of €99 and above: Qualify for free shipping.

How to buy The xTool P2 in others EU country?

Visit xTool EU store and benefit from free shipping on all orders over 99 €. Here you can buy the essentials, including the xTool P2. Shipments are made 1 to 3 working days after receipt of payment from the DE warehouse.

Common Troubleshooting

When using the xTool P2 laser machine, it is common to encounter some issues. In this section, we will provide you with some basic troubleshooting steps to help you maintain and operate your machine confidently and efficiently. Remember to always refer to the xTool P2 User Guide for complete instructions and safety guidelines.

If you notice that the machine is not functioning properly when the power indicator is on, it could be due to the emergency stop switch being engaged. To resolve this, locate the emergency stop switch on the right side of the machine and turn it to reset its position.

In case you encounter an error code while using the XCS (xTool Creative Space) Software, refer to the troubleshooting guide provided for specific error codes and steps to resolve the issue.

If your laser module is not moving properly, first check the casing of the machine for any visible damage. In case of severe damage, do not use the machine and contact xTool after-sales services. If the casing is intact, manually move the laser module to confirm its proper movement.

A common issue that users face is the inaccuracy in processing results. This can be caused by inaccurate focusing or using a low-definition picture. To resolve the focusing issue, follow these steps:

- Place your material under the laser head.

- Lower the support bar, loosen the rotating screw, and let the support bar touch the material.

- Prop up the support bar, tighten it manually, and fix the screw.

If you are still facing issues with the accuracy or quality of your results, consider using a higher-definition image for your project.

Keep these troubleshooting tips in mind while working with your xTool P2 laser machine, and you’ll be able to overcome common challenges with ease.